A comprehensive pyrolysis initiative designed to process waste tyres into valuable resources whilst training the next generation of environmental technology specialists.

South Africa faces an escalating waste tyre crisis. With inadequate infrastructure and accelerating waste generation, the situation demands immediate, innovative intervention.

Storage facilities have reached capacity. Major tyre fires have devastated communities. Government regulations have intensified. Yet approximately 11 million waste tyres are generated annually, and current infrastructure cannot adequately address the existing stockpile of millions of tyres across the country.

The proposed facility will utilise state-of-the-art thermal decomposition technology to convert waste tyres into four distinct, commercially valuable materials, achieving complete resource recovery with minimal environmental impact.

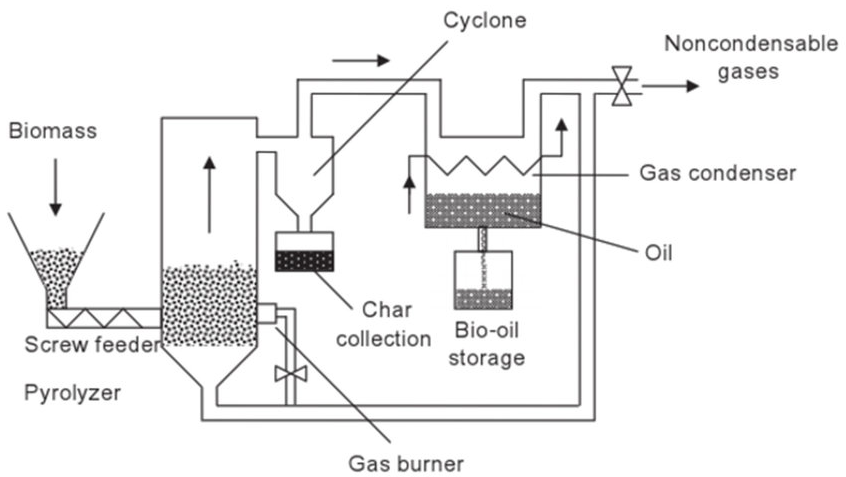

In an oxygen-free, high-temperature environment, molecular bonds in waste tyres decompose, separating into pure components. Every kilogramme of waste becomes a kilogramme of usable material. No landfill, minimal emissions, zero environmental burden. This is the circular economy in practice.

High-grade liquid fuel recovered from thermal decomposition, suitable for industrial heating applications, power generation, or further refining into diesel and specialised petroleum products for commercial use.

Recovered carbon black powder with applications in toner cartridges, rubber manufacturing, and as a reinforcing agent in new tyre production, effectively closing the material loop.

Clean, high-quality steel wire extracted from tyre belts, ready for direct sale to scrap metal recyclers or steel manufacturers for reprocessing into new steel products.

Combustible synthesis gas produced during pyrolysis, captured and utilised to fuel the process itself, reducing external energy requirements and operational costs significantly.

Beyond waste management, this initiative represents a comprehensive approach to environmental technology education, skills development, and sustainable industrial practice in South Africa.

Establish a world-class training facility for environmental technology specialists, providing hands-on experience with advanced pyrolysis systems and circular economy principles for the next generation of professionals.

Demonstrate best-practice implementation of pyrolysis technology with full environmental compliance, setting new benchmarks for emission control, safety protocols, and operational efficiency in South Africa.

Prove the commercial viability of complete resource recovery from waste streams, creating valuable materials that re-enter productive use whilst eliminating environmental harm from disposal.

Reduce the burden on landfills, prevent toxic tyre fires, eliminate groundwater contamination risks, and contribute meaningfully to South Africa's environmental protection objectives.

Create sustainable employment opportunities whilst generating revenue from recovered materials, demonstrating that environmental responsibility and economic viability can successfully align.

Advance understanding of thermal decomposition processes, optimise output quality, and develop new applications for recovered materials through ongoing research and development initiatives.

Operating at full capacity, a single facility can make substantial progress towards addressing South Africa's waste tyre crisis whilst generating significant environmental and economic benefits.

Based on 8,000kg daily capacity operating 300 days annually, removing approximately 2.4 million kilogrammes of waste tyres from the waste stream each year.

Annual production of approximately 825,000 litres of industrial-grade fuel oil, reducing dependence on virgin petroleum products and creating new revenue streams.

Annual recovery of approximately 720 tonnes of carbon black for commercial applications, replacing virgin carbon black production and supporting local manufacturing.

Annual recovery of approximately 300 tonnes of clean steel wire, ready for immediate sale to recyclers and contributing to the circular metal economy.

Estimated prevention of 3,600 tonnes of CO₂ equivalent emissions annually compared to landfill disposal and virgin material production, a significant climate contribution.

Creation of direct employment in operations, maintenance, logistics, and administration, plus indirect opportunities in collection, transport, and material sales networks.

South Africa's waste tyre crisis represents both an environmental challenge and an economic opportunity. With proven technology, comprehensive planning, and commitment to environmental excellence, Bio-E Group is positioned to make a substantial contribution to sustainable waste management.

The infrastructure, technology, and expertise exist. What's required now is the investment and commitment to implement comprehensive solutions at the scale this crisis demands.